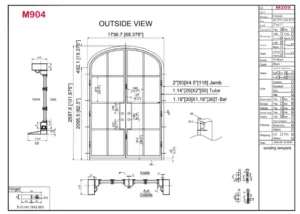

Description

- Fluoropolymer finishes are used on high-end steel roofing for its fade-resistance

- 80% more effective than powder coating for its’ impact-resistance, scratch-resistance, UV resistance, frost resistance and fade-resistance

- Finish goes through 5 baking processes (between coats)

- Application procedure

- Sandblast to clean and de-bur

- Zinc-rich epoxy primer (1st bake)

- Mica iron epoxy primer (2nd bake)

- Metal filler applied for welded areas-2 applications (3-4th bake)

- Intermediate coat followed by inspection process

- Paint application (Urethane blend)-2 applications

- Clear coat sealer applied (multi-coat)

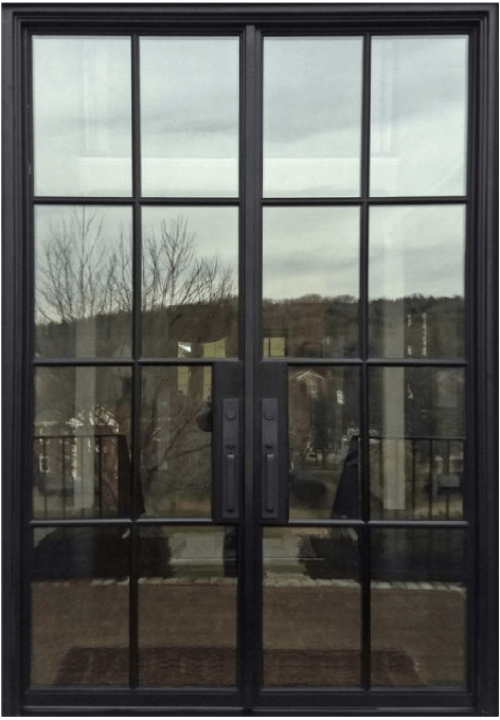

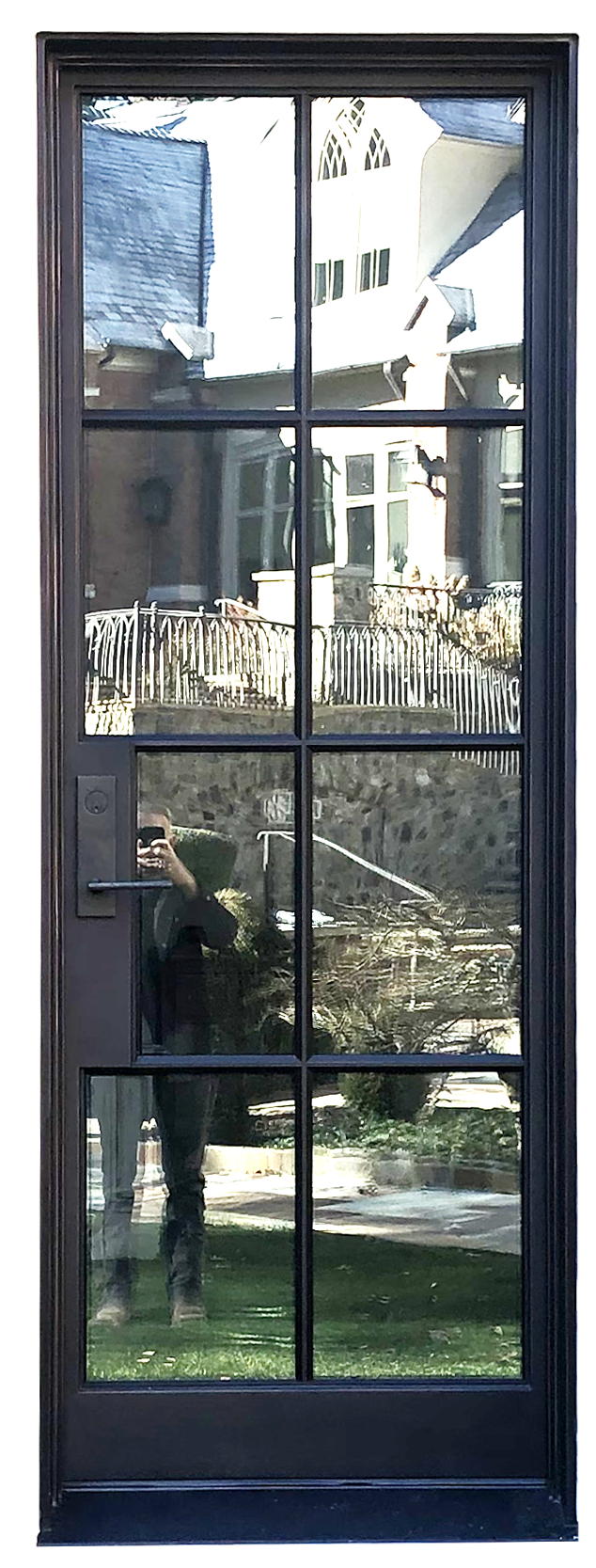

- Heavy 12-gauge steel (30% thicker than 14-gauge) with a Fluoropolymer finish

- True divided lite glass partitions, Available with PPG Solarban LowE (Argon) glass with .264 U-value

- Q-Lon weather-stripping: pre-installed in jamb, t-astragal, and operable window frames

- 1.18” Beveled edge aluminum glass beads on exterior side & steel T-Bar on interior side

- Machined steel hinges with brass bushings rated at 800 lbs. capacity per hinge

- Door and jamb insulated with dense closed-cell polyurethane foam using a computerized machine measuring backflow and penetration for 100% fill